Predictive maintenance

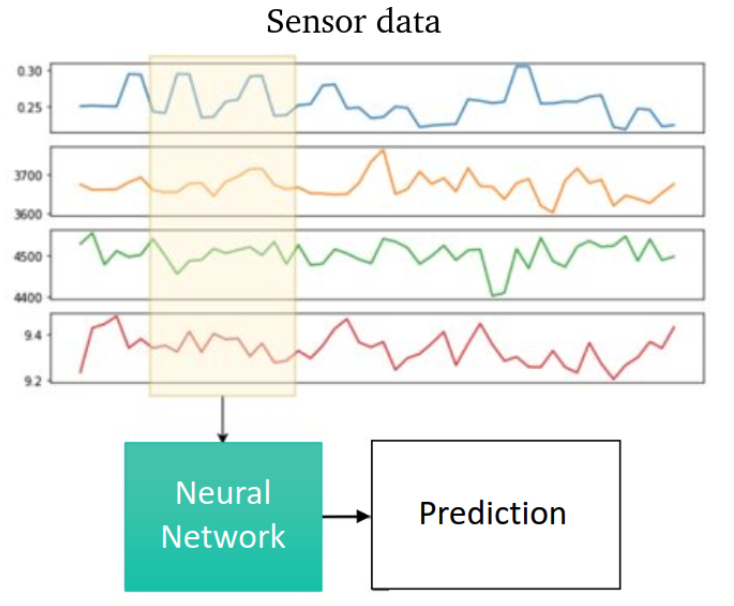

Predictive maintenance is an advanced approach in industrial data analytics that uses sensor data to forecast equipment conditions.

This data typically consists of multivariate time series, capturing parameters such as vibration, temperature, pressure, and other operational metrics. Machine learning and deep learning techniques enable predictive maintenance to address key challenges: diagnosing equipment health, detecting anomalies and early failure signs, and estimating components' remaining useful life (RUL).

By analyzing these patterns, predictive maintenance facilitates proactive maintenance—reducing unplanned downtime, optimizing repair schedules, and preventing costly breakdowns.

Directions:

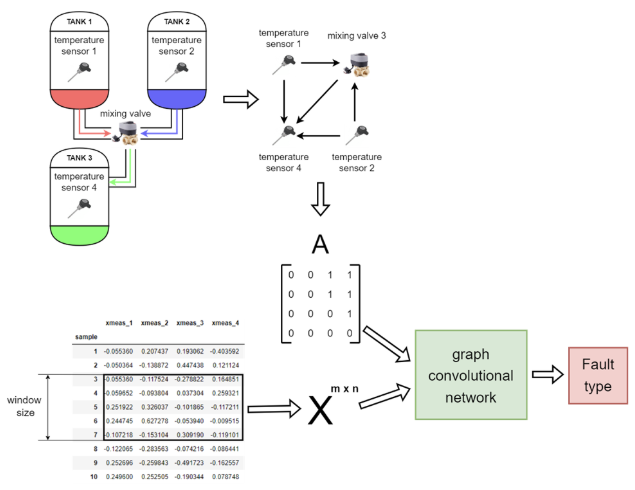

Graph Neural Networks

GNNs take into account information about the relationships between equipment components

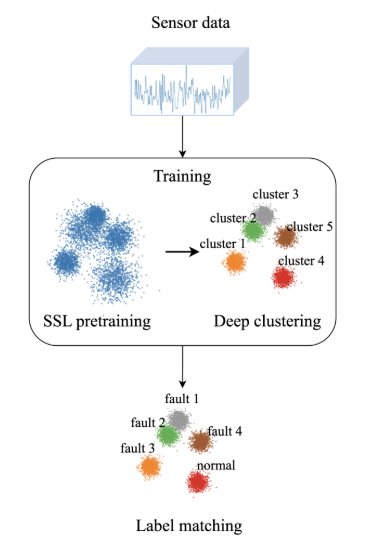

Self-supervised learning

SSL methods enable learning from unlabeled and sparsely labeled data

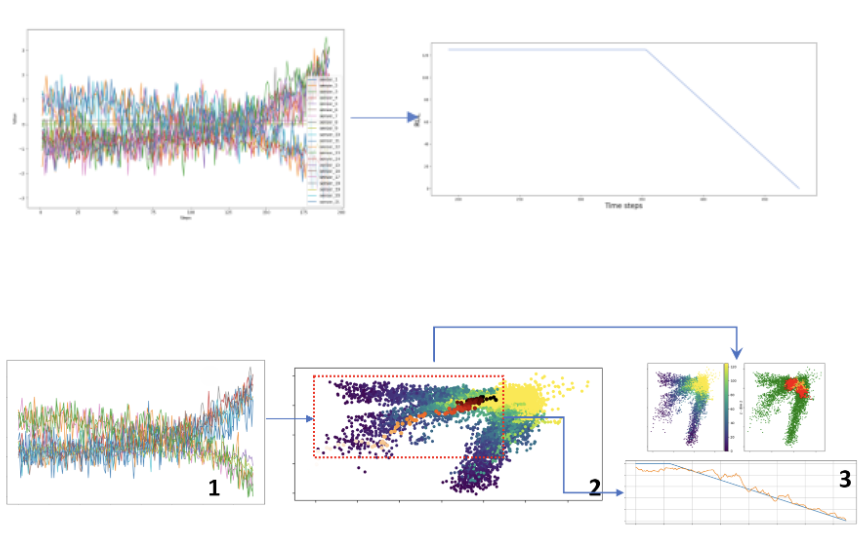

Remaining Useful Life

RUL techniques enable the forecasting of the remaining useful life of equipment units

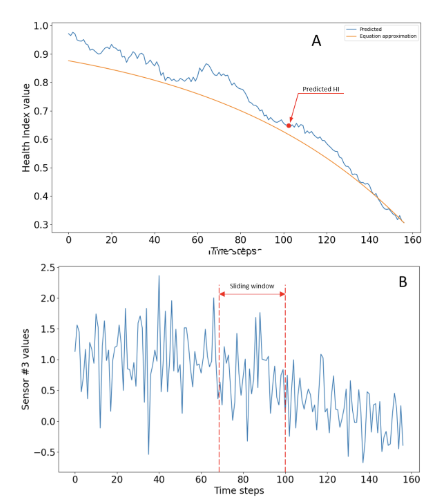

Health Index

HI methods allow for assessing the current health of equipment components

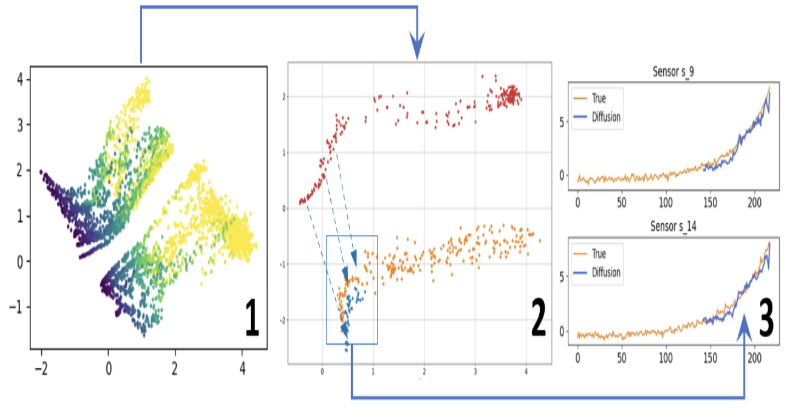

Virtual sensors

VS techniques allow for creating software analogs of missing physical sensors

Embedded AI

Embedded AI enable intelligent functions on edge devices without a constant cloud connection

Participants

Ilya Makarov

Team lead

Andrei Zakharov

Project lead

Aleksandr Kovalenko

ML Researcher

Dmitry Zhevnenko

Project lead